ໂທຫາພວກເຮົາ

+86-19858305627

ສົ່ງອີເມວຫາພວກເຮົາ

sales@maple-machinery.com

ການແກ້ໄຂການຫລໍ່ເຫລໍກສໍາລັບການຂຸດຄົ້ນນ້ໍາມັນແລະອາຍແກັສ ຜູ້ຜະລິດ

ໂຮງງານຜະລິດຂອງພວກເຮົາສະຫນອງການຫລໍ່ດິນຊາຍ, ປິດ forging ຕາຍ, ເປີດ forging, ແລະອື່ນໆ. ການອອກແບບທີ່ສຸດ, ວັດຖຸດິບທີ່ມີຄຸນນະພາບ, ປະສິດທິພາບສູງແລະລາຄາທີ່ແຂ່ງຂັນແມ່ນສິ່ງທີ່ລູກຄ້າຕ້ອງການ, ແລະນັ້ນແມ່ນສິ່ງທີ່ພວກເຮົາສາມາດສະເຫນີໃຫ້ທ່ານ. ພວກເຮົາເອົາຄຸນນະພາບສູງ, ລາຄາທີ່ເຫມາະສົມແລະການບໍລິການທີ່ສົມບູນແບບ.

ຜະລິດຕະພັນຮ້ອນ

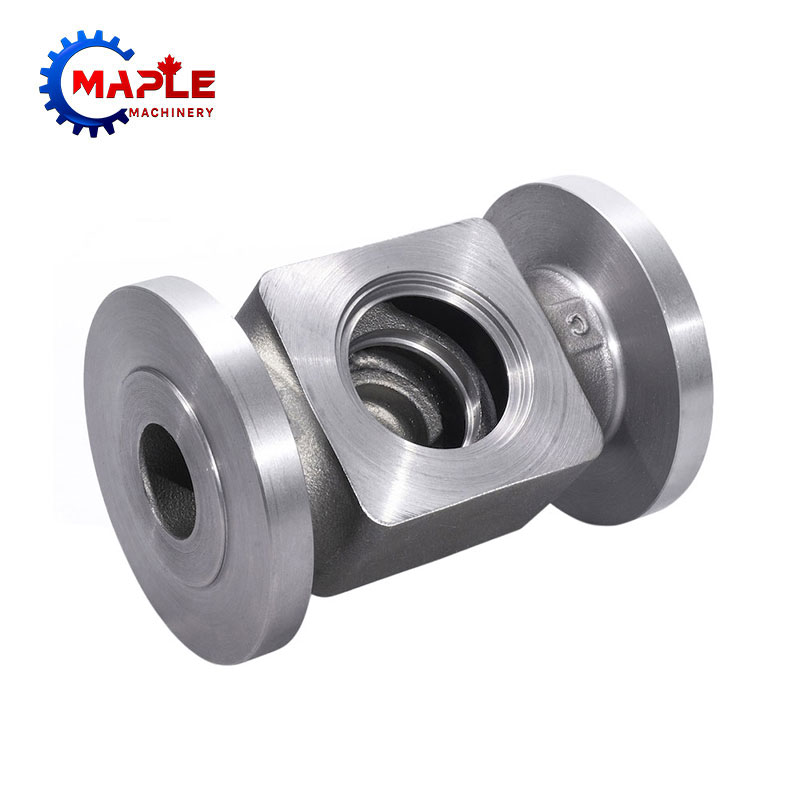

ນ້ຳມັນ ແລະ ອາຍແກັສ ເຫຼັກກ້າ ຊິ້ນສ່ວນການຫລໍ່ດິນຊາຍ

ເຄື່ອງຈັກ Maple ຜະລິດຊິ້ນສ່ວນການຫລໍ່ຫລໍ່ຫລອມເຫຼັກກ້າຊາຍແລະອຸດສາຫະກໍານ້ໍາມັນທີ່ມີຄຸນນະພາບສໍາລັບອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສທົ່ວໂລກ. ເປົ້າຫມາຍຂອງພວກເຮົາແມ່ນເພື່ອສະຫນອງທາງເລືອກໃນຕະຫຼາດແລະການແກ້ໄຂທີ່ເຊື່ອຖືໄດ້ຫຼາຍສໍາລັບ Oil & Gas Industry Steel Sand Casting Parts Parts, ແລະເພື່ອຮັບປະກັນວ່າໂດຍການສ້າງຊິ້ນສ່ວນທີ່ມີຄຸນນະພາບສູງ, ບໍ່ພຽງແຕ່ຈະໃຊ້ໄດ້ດົນກວ່າແລະຖືກສະຫນອງຕາມເວລາ, ແຕ່ຍັງມີຄ່າໃຊ້ຈ່າຍຕ່ໍາ, ດັ່ງນັ້ນການຫຼຸດຜ່ອນເສດຖະກິດທີ່ໃຊ້ເວລາຂອງລູກຄ້າເຊັ່ນ: ພາກສ່ວນທີ່ມີຄຸນນະພາບສູງສຸດ.Off ທາງດ່ວນອຸດສາຫະ ກຳ ສະແຕນເລດ Casting Parts

ເພື່ອໃຫ້ຕົວກໍານົດການ Casting ທີ່ດີທີ່ສຸດສໍາລັບຜະລິດຕະພັນທີ່ຮ້ອງຂໍ, ເຄື່ອງຈັກ Maple ຜະລິດ Off Highway Stainless Steel Casting Parts ໂດຍໃຊ້ເຕັກໂນໂລຢີ CAD ຫລ້າສຸດເພື່ອໃຫ້ລູກຄ້າຂອງພວກເຮົາມີແມ່ພິມສີດຂີ້ເຜີ້ງໃນລາຄາທີ່ແຂ່ງຂັນ. fixture ທີ່ສະຫນອງແລະສະຫນັບສະຫນູນຄວາມສອດຄ່ອງຂອງມິຕິລະດັບຂອງ mold ສີດຂີ້ເຜີ້ງແມ່ນອອກແບບດ້ວຍຕົນເອງຕາມຂະຫນາດຂອງຮູບແຕ້ມດ້ານວິຊາການຂອງພາກສ່ວນເພື່ອເຮັດຊ້ໍາຄວາມຖືກຕ້ອງຂອງການວັດແທກ.ເຄື່ອງຈັກກໍ່ສ້າງ Ductile Iron Casting Parts

ບໍລິສັດມີຫຼາຍກ່ວາສິບປີຂອງປະສົບການໃນການກໍ່ສ້າງເຄື່ອງຈັກ Ductile Iron Casting Parts. ໂດຍການນໍາໃຊ້ຄອມພິວເຕີແລະສາຍການຜະລິດອັດຕະໂນມັດ, ພວກເຮົາສາມາດໄດ້ຮັບທີ່ດີທີ່ສຸດຈາກວິທີການຫລໍ່ນີ້, ການສ້າງຮູບຮ່າງທີ່ຊັບຊ້ອນ, ການຜະລິດສາຍກົດ, ກໍາຈັດເສັ້ນແຍກ, ແລະການຜະລິດຫລໍ່ທີ່ມີຄວາມທົນທານມິຕິລະດັບສູງທີ່ສຸດ.ວິສະວະກໍາໂຍທາ Steel Precision Casting Parts

ເຄື່ອງຈັກ Maple ເປັນຜູ້ຜະລິດເຫຼັກ Precision Casting Parts ສໍາລັບຄວາມຫລາກຫລາຍຂອງຄວາມຕ້ອງການອຸດສາຫະກໍາ. ພວກເຮົາພູມໃຈໃນຕົວເຮົາເອງໃນການເພີ່ມມູນຄ່າໃຫ້ກັບສ່ວນການຫລໍ່ເຫຼັກ Precision Casting ຂອງທ່ານ. Civil Engineering Steel Precision Casting Parts is one of our many products, We are experienced in manufacturing Civil Engineering Steel Precision Casting Parts. ຄວາມຫມັ້ນໃຈແມ່ນມາຈາກປະສົບການການຜະລິດຂອງພວກເຮົາຫຼາຍກວ່າ 15 ປີ.ນ້ຳມັນ ແລະ ອາຍແກັສ ຊິ້ນສ່ວນການຫລໍ່ເຫຼັກ

Maple ແມ່ນໂຮງງານຜະລິດແລະໂຮງງານປຸງແຕ່ງທີ່ໄດ້ຮັບການຮັບຮອງ ISO ທີ່ມີປະສົບການອັນອຸດົມສົມບູນໃນການຜະລິດຊິ້ນສ່ວນເຫຼັກກ້າຂອງນ້ໍາມັນແລະອາຍແກັສ. ຜູ້ຊ່ຽວຊານດ້ານການລົງທືນຂອງພວກເຮົາຈະໃຫ້ຄວາມຊ່ວຍເຫຼືອທັງໝົດແກ່ເຈົ້າ, ຕັ້ງແຕ່ການແກ້ໄຂບັນຫາການອອກແບບ ຈົນເຖິງການເລືອກໂລຫະປະສົມທີ່ເໝາະສົມກັບສະພາບແວດລ້ອມການເຮັດວຽກຂອງເຈົ້າ.ອຸດສາຫະ ກຳ ຣີໄຊເຄິນຊິ້ນສ່ວນການຫລໍ່ດ້ວຍຊາຍຊາຍ

ເຄື່ອງຈັກ Maple ແມ່ນໂຮງງານຜະລິດເຫຼັກກ້າສີຂີ້ເຖົ່າ ແລະ ductile ທີ່ມີຄຸນນະພາບສູງສໍາລັບອຸດສາຫະກໍາລີໄຊເຄີນ. ບໍລິສັດແມ່ນຢູ່ແຖວຫນ້າຂອງຈຸດປະສົງເພື່ອເພີ່ມປະສິດທິພາບຄວາມພໍໃຈຂອງລູກຄ້າແລະຄຸນນະພາບສູງ, ແລະສະຫນອງຄຸນນະພາບສູງຂອງອຸດສາຫະກໍາ Recycling Sand Casting Parts ດິນຊາຍເພື່ອສະຫນອງການບໍລິການສະຫນັບສະຫນູນທີ່ສໍາຄັນເຊັ່ນ: ການຜະລິດ mold ແລະການບໍລິການເກັບຮັກສາ, ການທົດສອບແລະການປະເມີນຜົນໂລຫະ, prototyping, ພາກສ່ວນ. ສໍາເລັດຮູບ, ການປຸງແຕ່ງ, ການເຄືອບແລະການປິ່ນປົວຄວາມຮ້ອນ.

ສົ່ງສອບຖາມ

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy