ໂທຫາພວກເຮົາ

+86-19858305627

ສົ່ງອີເມວຫາພວກເຮົາ

sales@maple-machinery.com

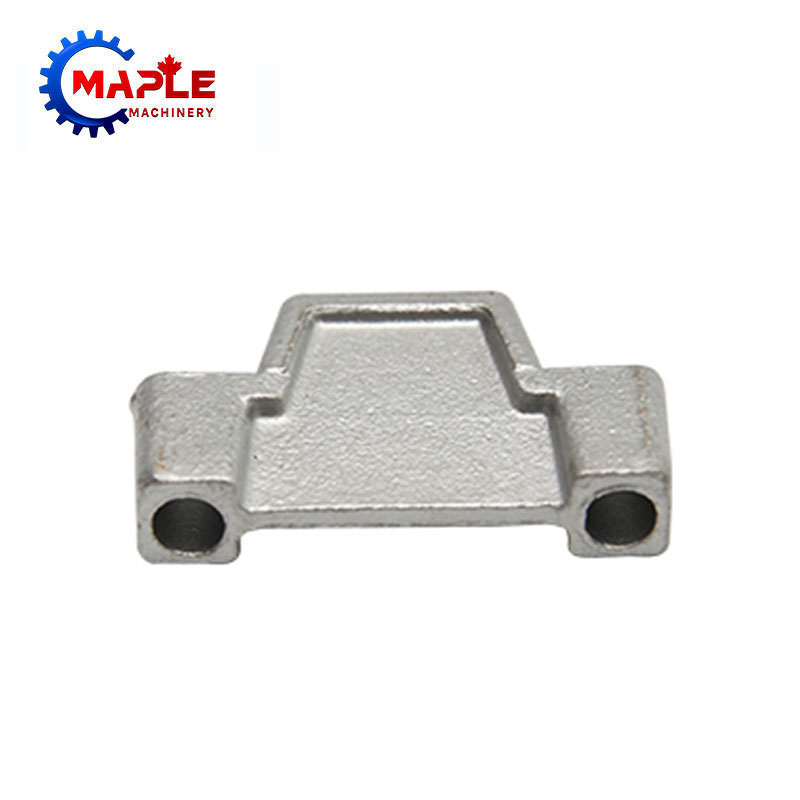

ການຫລໍ່ເຫລໍກທີ່ຫນັກແຫນ້ນສໍາລັບຂະແຫນງນ້ໍາມັນແລະອາຍແກັສ ຜູ້ຜະລິດ

ໂຮງງານຜະລິດຂອງພວກເຮົາສະຫນອງການຫລໍ່ດິນຊາຍ, ປິດ forging ຕາຍ, ເປີດ forging, ແລະອື່ນໆ. ການອອກແບບທີ່ສຸດ, ວັດຖຸດິບທີ່ມີຄຸນນະພາບ, ປະສິດທິພາບສູງແລະລາຄາທີ່ແຂ່ງຂັນແມ່ນສິ່ງທີ່ລູກຄ້າຕ້ອງການ, ແລະນັ້ນແມ່ນສິ່ງທີ່ພວກເຮົາສາມາດສະເຫນີໃຫ້ທ່ານ. ພວກເຮົາເອົາຄຸນນະພາບສູງ, ລາຄາທີ່ເຫມາະສົມແລະການບໍລິການທີ່ສົມບູນແບບ.

ຜະລິດຕະພັນຮ້ອນ

ຂະບວນການອາຫານເຄື່ອງຈັກ Steel Casting ການລົງທຶນ

ເຄື່ອງຈັກ Maple ມີຄວາມສາມາດສົມບູນໃນການພັດທະນາເຕັກໂນໂລຊີຫລໍ່ຫລໍ່ຄວາມແມ່ນຍໍາ ປະສົບການການສົ່ງອອກຫຼາຍກວ່າ 15 ປີ, ສະຫນອງພາກສ່ວນທີ່ມີຄຸນນະພາບສູງ, ເຊິ່ງຊ່ວຍປັບປຸງປະສິດທິພາບການຜະລິດແລະຄວາມແມ່ນຍໍາໃນການປຸງແຕ່ງຢ່າງຫຼວງຫຼາຍ. ພວກເຮົາມີປະສົບການອຸດົມສົມບູນໃນເຄື່ອງຈັກປຸງແຕ່ງສະບຽງອາຫານ, ແລະຈະຜະລິດຈໍານວນຫຼາຍຂອງຂະບວນການອາຫານເຄື່ອງຈັກເຫຼັກກ້າ Casting ການລົງທຶນສໍາລັບລູກຄ້າທຸກໆປີ.ຂະບວນການອາຫານເຄື່ອງຈັກ Steel Sand Casting Parts

ເຄື່ອງຈັກ Maple ແມ່ນບໍລິສັດທີ່ມີຄວາມຊ່ຽວຊານໃນການປຸງແຕ່ງໂລຫະ, ການຫລໍ່ໂລຫະ, ເຄື່ອງຈັກ CNC ຄວາມແມ່ນຍໍາ. ພວກເຮົາມີຄວາມຊ່ຽວຊານໃນຂະບວນການຜະລິດອາຫານທີ່ກໍາຫນົດເອງເຄື່ອງຈັກ Steel Sand Casting Parts ການຜະລິດແລະມີວິສະວະກອນຜູ້ຊ່ຽວຊານເພື່ອສະຫນັບສະຫນູນການບໍລິການສົ່ງອອກ. ວິສະວະກອນຂອງພວກເຮົາມີຄວາມຄຸ້ນເຄີຍກັບລະດັບແລະມາດຕະຖານສາກົນ. ພວກເຂົາເຈົ້າໄດ້ເຮັດວຽກໃນຂະແຫນງການສົ່ງອອກສໍາລັບເກືອບສິບປີ. ພວກເຮົາສະຫນອງການແກ້ໄຂທີ່ເຊື່ອຖືໄດ້ແລະລາຄາບໍ່ແພງສໍາລັບຜະລິດຕະພັນໂລຫະ. ພວກເຮົາສາມາດໃຊ້ໂຄງປະກອບການຕົ້ນທຶນຕ່ໍາຂອງພວກເຮົາໃນປະເທດຈີນເພື່ອໃຫ້ຜະລິດຕະພັນຕົ້ນທຶນຕ່ໍາແລະເຊື່ອຖືໄດ້ໃນອັດຕາຕ່ໍາຜູ້ສະຫນອງໃນເກືອບທຸກປະເທດ. ທີມງານຂອງພວກເຮົາມີປະສົບການຜູ້ຈັດການໂຄງການ, ວິສະວະກອນແລະຜູ້ຊ່ຽວຊານດ້ານການຮັບປະກັນຄຸນນະພາບການຄຸ້ມຄອງໂຄງການຈັດຊື້ແລະການຜະລິດເປັນການພົວພັນຈີນຂອງລູກຄ້າຂອງພວກເຮົາ.ອຸດສາຫະກໍາຂຸດຄົ້ນບໍ່ແຮ່ເຫຼັກສະແຕນເລດ Forging Parts

ເຄື່ອງຈັກ Maple ຜະລິດເຫຼັກສະແຕນເລດ forgings. ພວກເຮົາພັດທະນາແລະຜະລິດອຸດສາຫະກໍາການຂຸດຄົ້ນບໍ່ແຮ່ເຫຼັກສະແຕນເລດ Forging Parts ຕາມຮູບແຕ້ມຫຼືຕົວຢ່າງສະຫນອງໃຫ້ໂດຍລູກຄ້າ. ກ່ອນອື່ນ ໝົດ, ພວກເຮົາເຮັດການກວດສອບທີ່ສອດຄ້ອງກັນຫຼັງຈາກແຕ່ລະຂະບວນການ. ສໍາລັບຜະລິດຕະພັນສຸດທ້າຍ, ພວກເຮົາຈະດໍາເນີນການກວດກາຢ່າງເຕັມທີ່ 100% ຕາມຄວາມຕ້ອງການຂອງລູກຄ້າແລະມາດຕະຖານສາກົນ. ດ້ວຍຄຸນນະພາບທີ່ດີເລີດ, ການບໍລິການທີ່ມີຄຸນນະພາບສູງແລະລາຄາທີ່ແຂ່ງຂັນ, ລູກຄ້າອຸດສາຫະກໍາຂຸດຄົ້ນບໍ່ແຮ່ໄວ້ວາງໃຈ.Off ທາງດ່ວນອຸດສາຫະກໍາເຫຼັກ Forging Parts

Maple forging ແມ່ນບໍລິສັດຜະລິດແລະວິສະວະກໍາທີ່ມີນະວັດກໍາຂອງຈີນທີ່ປະສົມປະສານການພັດທະນາແລະການຜະລິດຜະລິດຕະພັນເພື່ອຜະລິດຊິ້ນສ່ວນເຫຼັກ Forging ອຸດສາຫະກໍາທາງດ່ວນ. ຫຼັກຊັບຜະລິດຕະພັນທີ່ສົມບູນແບບຂອງພວກເຮົາກໍານົດມາດຕະຖານອຸດສາຫະກໍາທີ່ມີຄຸນນະພາບດີເລີດຢ່າງຕໍ່ເນື່ອງ. Maple ມີຊັບພະຍາກອນແລະຄວາມສາມາດໃນການສະຫນອງການແກ້ໄຂຄວາມຕ້ອງການຂອງອຸດສາຫະກໍາໃນປະຈຸບັນ, ໃນຂະນະທີ່ພັດທະນາເຕັກໂນໂລຢີການຜະລິດໃຫມ່ເພື່ອສະຫນັບສະຫນູນອະນາຄົດຂອງມັນ.ນ້ຳມັນ ແລະ ອາຍແກັສ ເຫຼັກກ້າ ຊິ້ນສ່ວນການຫລໍ່ດິນຊາຍ

ເຄື່ອງຈັກ Maple ຜະລິດຊິ້ນສ່ວນການຫລໍ່ຫລໍ່ຫລອມເຫຼັກກ້າຊາຍແລະອຸດສາຫະກໍານ້ໍາມັນທີ່ມີຄຸນນະພາບສໍາລັບອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສທົ່ວໂລກ. ເປົ້າຫມາຍຂອງພວກເຮົາແມ່ນເພື່ອສະຫນອງທາງເລືອກໃນຕະຫຼາດແລະການແກ້ໄຂທີ່ເຊື່ອຖືໄດ້ຫຼາຍສໍາລັບ Oil & Gas Industry Steel Sand Casting Parts Parts, ແລະເພື່ອຮັບປະກັນວ່າໂດຍການສ້າງຊິ້ນສ່ວນທີ່ມີຄຸນນະພາບສູງ, ບໍ່ພຽງແຕ່ຈະໃຊ້ໄດ້ດົນກວ່າແລະຖືກສະຫນອງຕາມເວລາ, ແຕ່ຍັງມີຄ່າໃຊ້ຈ່າຍຕ່ໍາ, ດັ່ງນັ້ນການຫຼຸດຜ່ອນເສດຖະກິດທີ່ໃຊ້ເວລາຂອງລູກຄ້າເຊັ່ນ: ພາກສ່ວນທີ່ມີຄຸນນະພາບສູງສຸດ.ອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສສະແຕນເລດ Forging Parts

ເຄື່ອງຈັກ Maple ຕັ້ງຢູ່ໃນ Ningbo, ປະເທດຈີນສໍາລັບພາກສ່ວນການຜະລິດ, ສາງແລະການຂົນສົ່ງຍ່ອຍຂອງອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສສະແຕນເລດ Forging Parts, ແລະມີຕໍາແຫນ່ງທີ່ດີເພື່ອຕອບສະຫນອງຄວາມຕ້ອງການຂອງຜູ້ສະຫນອງທີ່ສໍາຄັນໃນອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສ. ສົມທົບກັບຜູ້ສະຫນອງທີ່ໄດ້ຮັບການຢັ້ງຢືນແລະອະນຸມັດຈາກລູກຄ້າຂອງພວກເຮົາໃນຫຼາຍໆປະເທດ, ທ່ານມີໂອກາດທີ່ຈະໃຊ້ປະໂຫຍດຈາກຜົນປະໂຫຍດຂອງແຫຼ່ງທີ່ມາໃນປະເທດທີ່ມີລາຄາຖືກແລະຮູ້ວ່າຂໍຂອບໃຈກັບຜະລິດຕະພັນ Maple ມີການຮັບປະກັນຄຸນນະພາບ 100%.

ສົ່ງສອບຖາມ

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy