ໂທຫາພວກເຮົາ

+86-19858305627

ສົ່ງອີເມວຫາພວກເຮົາ

sales@maple-machinery.com

ການຫລໍ່ເຫລໍກສີຂີ້ເຖົ່າອຸດສາຫະກໍາ ຜູ້ຜະລິດ

ໂຮງງານຜະລິດຂອງພວກເຮົາສະຫນອງການຫລໍ່ດິນຊາຍ, ປິດ forging ຕາຍ, ເປີດ forging, ແລະອື່ນໆ. ການອອກແບບທີ່ສຸດ, ວັດຖຸດິບທີ່ມີຄຸນນະພາບ, ປະສິດທິພາບສູງແລະລາຄາທີ່ແຂ່ງຂັນແມ່ນສິ່ງທີ່ລູກຄ້າຕ້ອງການ, ແລະນັ້ນແມ່ນສິ່ງທີ່ພວກເຮົາສາມາດສະເຫນີໃຫ້ທ່ານ. ພວກເຮົາເອົາຄຸນນະພາບສູງ, ລາຄາທີ່ເຫມາະສົມແລະການບໍລິການທີ່ສົມບູນແບບ.

ຜະລິດຕະພັນຮ້ອນ

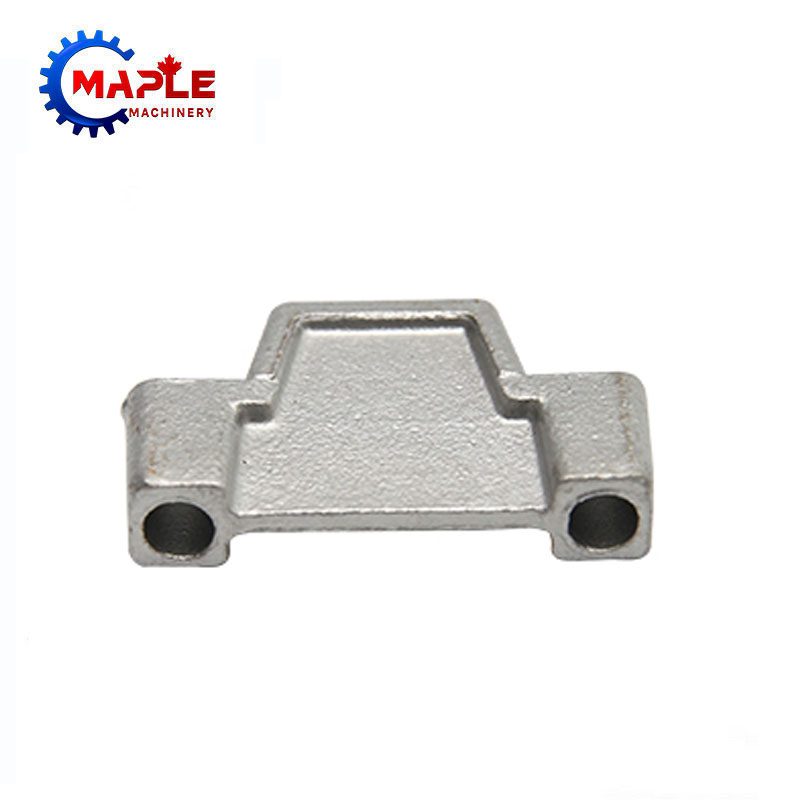

ກົນຈັກກໍ່ສ້າງ ຊິ້ນສ່ວນການຫລໍ່ດ້ວຍດິນຊາຍ

Maple Machinery ເປັນຜູ້ຜະລິດນະວັດຕະກໍາຂອງການຫລໍ່ເຫລໍກແລະເຫຼັກກ້າທີ່ມີຄຸນນະພາບສູງ, ມີສໍານັກງານໃຫຍ່ຢູ່ໃນ Ningbo, ປະເທດຈີນ. ມັນເປັນຜູ້ສະຫນອງຊັ້ນນໍາທີ່ໄດ້ຮັບການຍອມຮັບໃນທົ່ວໂລກຂອງເຄື່ອງຈັກໃນການກໍ່ສ້າງໂລຫະປະສົມດິນຊາຍທີ່ມີຄວາມແມ່ນຍໍາສູງແລະຄວາມຊັບຊ້ອນສູງ. ທີມງານຂອງພວກເຮົາຫມັ້ນສັນຍາກັບຄຸນນະພາບຂອງແຕ່ລະໂຄງການເພື່ອຮັບປະກັນຄວາມພໍໃຈຂອງລູກຄ້າສູງສຸດ.ຂະບວນການອາຫານເຄື່ອງຈັກທາດເຫຼັກຊາຍ Casting Parts

ສຽງໂຫວດທັງຫມົດທີ່ມີຄຸນນະພາບສູງ, ຊິ້ນສ່ວນເຄື່ອງຈັກໃນລາຄາທີ່ແຂ່ງຂັນຈາກຜູ້ສະຫນອງທີ່ເຊື່ອຖືໄດ້. Maple Machinery ເປັນຜູ້ຜະລິດຊິ້ນສ່ວນໂລຫະທີ່ມີຊື່ສຽງໃນປະເທດຈີນແລະເປັນຜູ້ສະຫນອງທີ່ເຊື່ອຖືໄດ້ຂອງເຄື່ອງຈັກຂະບວນການອາຫານ. ເຄື່ອງປຸງແຕ່ງອາຫານຕ້ອງການເຄື່ອງປຸງແຕ່ງອາຫານທີ່ມີຄວາມແມ່ນຍໍາສູງ ທາດເຫຼັກ ເຫຼັກຊາຍ Casting Parts. ພວກເຮົາສາມາດເຮັດວຽກທີ່ດີຂອງຜູ້ສະຫນອງຜະລິດຕະພັນທີ່ສໍາຄັນຂອງອົງປະກອບລະບົບທີ່ສໍາຄັນທັງຫມົດ.ເຄື່ອງຈັກກໍ່ສ້າງສະແຕນເລດ Forging Parts

ເຄື່ອງຈັກ Maple ມີການແກ້ໄຂທີ່ເຫມາະສົມ. ໃຊ້ການບໍລິການເຄື່ອງຈັກ CNC ເພື່ອເຮັດໃຫ້ຂະບວນການຜະລິດງ່າຍຂຶ້ນ. ມັນຊ່ວຍໃຫ້ທ່ານເລັ່ງການຜະລິດຊິ້ນສ່ວນທີ່ຖືກປຸງແຕ່ງດ້ວຍລະດັບຄວາມແມ່ນຍໍາແລະຄວາມແມ່ນຍໍາສູງສຸດ. ເຄື່ອງຈັກ Maple ສາມາດໃຫ້ທ່ານອອນໄລນ໌ໄວ CNC machining ເຄື່ອງຈັກການກໍ່ສ້າງສະແຕນເລດ Forging Parts ຕາມຄວາມຕ້ອງການສະເພາະຂອງທ່ານ. ພວກເຮົາສະເຫນີໃຫ້ທ່ານຄໍາຮ້ອງສະຫມັກການບໍລິການ machining ໄວແລະພາກສ່ວນຂະບວນການສໍາລັບທ່ານໃນເວລາສັ້ນທີ່ສຸດທີ່ເປັນໄປໄດ້.ເຄື່ອງຈັກການກະເສດສະແຕນເລດ Casting Parts

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.ວິສະວະກຳໂຍທາ

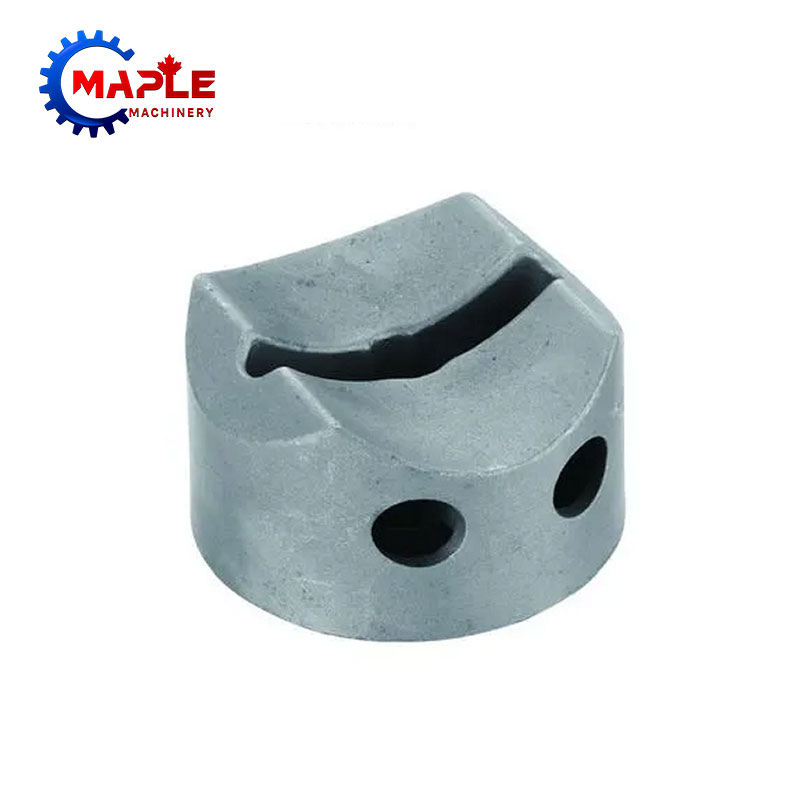

ນັບຕັ້ງແຕ່ການເລີ່ມຕົ້ນຂອງບໍລິສັດ, ເຄື່ອງຈັກ Maple Iron Sand Casting Parts ໄດ້ມີຄວາມຊ່ຽວຊານໃນການຜະລິດເຫຼັກກ້າທີ່ມີຄຸນນະພາບສູງແລະສະລັບສັບຊ້ອນສໍາລັບອຸດສາຫະກໍາຈໍານວນຫລາຍຕັ້ງແຕ່ມື້ຫນຶ່ງ. ພວກເຮົາໃຫ້ລູກຄ້າຂອງພວກເຮົາມີການແກ້ໄຂທີ່ສົມບູນສໍາລັບອົງປະກອບອາລູມິນຽມ. ໃນອົງການຈັດຕັ້ງຂອງພວກເຮົາ, ພວກເຮົາປະຕິບັດແຕ່ລະຂະບວນການຍ່ອຍທີ່ກ່ຽວຂ້ອງກັບການຜະລິດການຫລໍ່ສະລັບສັບຊ້ອນ. ນີ້ຮັບປະກັນການແກ້ໄຂບັນຫາການຫລໍ່ຫລໍ່ຫລອມດິນຊາຍແບບວິສະວະກໍາໂຍທາທີ່ສົມບູນທີ່ລູກຄ້າໄດ້ຮັບຜົນປະໂຫຍດຈາກຄຸນນະພາບທີ່ເຫນືອກວ່າແລະຄວາມຫນ້າເຊື່ອຖືທີ່ພວກເຂົາມີສິດທີ່ຈະຄາດຫວັງຈາກຜູ້ສະຫນອງຊິ້ນສ່ວນການຫລໍ່ເຫລໍກເຫຼັກຂອງພວກເຂົາ.ນ້ຳມັນ ແລະ ອາຍແກັສ ອຸດສາຫະ ກຳ ຊິ້ນສ່ວນການຫລໍ່ເຫລໍກສີຂີ້ເຖົ່າ

ຈາກວິສະວະກອນ Grey Iron Casting, ນັກວິຊາການ, foremen, ເຄື່ອງຈັກສ້າງແບບຈໍາລອງແລະຜູ້ສ້າງແບບຈໍາລອງໃນການຜະລິດໄປຫານັກວິຊາການກົນຈັກອຸດສາຫະກໍາແລະເອເລັກໂຕຣນິກຫຼືຜູ້ຊ່ວຍການຄຸ້ມຄອງອຸດສາຫະກໍາໃນການບໍາລຸງຮັກສາ, ພວກເຂົາເຮັດດີທີ່ສຸດທຸກໆມື້ເພື່ອກະລຸນາລູກຄ້າອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສຂອງພວກເຮົາດ້ວຍການຫລໍ່ທີ່ມີຄຸນນະພາບສູງ. ຈາກການໃຫ້ຄໍາປຶກສາແລະການປຸງແຕ່ງຄໍາສັ່ງ, ການກະກຽມການເຮັດວຽກແລະການຜະລິດຂອງ Oil & Gas ອຸດສາຫະກໍາການຫລໍ່ເຫລໍກສີຂີ້ເຖົ່າ, ການປຸງແຕ່ງເລິກແລະການຂົນສົ່ງ, ເປັນທີມ, ພວກເຮົາດໍາເນີນການເປົ້າຫມາຍທົ່ວໄປ: ເພື່ອຜະລິດຊິ້ນສ່ວນຫລໍ່ເຫລໍກສີຂີ້ເຖົ່າທີ່ຊັບຊ້ອນແລະມີຄຸນນະພາບສູງ.

ສົ່ງສອບຖາມ

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy