ໂທຫາພວກເຮົາ

+86-19858305627

ສົ່ງອີເມວຫາພວກເຮົາ

sales@maple-machinery.com

ອົງປະກອບການຫລໍ່ເຫຼັກອ່ອນສໍາລັບອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສ ຜູ້ຜະລິດ

ໂຮງງານຜະລິດຂອງພວກເຮົາສະຫນອງການຫລໍ່ດິນຊາຍ, ປິດ forging ຕາຍ, ເປີດ forging, ແລະອື່ນໆ. ການອອກແບບທີ່ສຸດ, ວັດຖຸດິບທີ່ມີຄຸນນະພາບ, ປະສິດທິພາບສູງແລະລາຄາທີ່ແຂ່ງຂັນແມ່ນສິ່ງທີ່ລູກຄ້າຕ້ອງການ, ແລະນັ້ນແມ່ນສິ່ງທີ່ພວກເຮົາສາມາດສະເຫນີໃຫ້ທ່ານ. ພວກເຮົາເອົາຄຸນນະພາບສູງ, ລາຄາທີ່ເຫມາະສົມແລະການບໍລິການທີ່ສົມບູນແບບ.

ຜະລິດຕະພັນຮ້ອນ

ນ້ຳມັນ ແລະ ອາຍແກັສ ອຸດສາຫະກຳເຫຼັກກ້າ ຊິ້ນສ່ວນການຫລໍ່ຂີ້ເຜີ້ງ

Maple ເປັນໂຮງງານຜະລິດແລະການປຸງແຕ່ງທີ່ມີປະສົບການຢ່າງກວ້າງຂວາງ, ແລະພວກເຮົາມີຄວາມຫມັ້ນໃຈອັນໃຫຍ່ຫຼວງທີ່ຈະເຮັດດີທີ່ສຸດໃນອຸດສາຫະກໍານ້ໍາມັນແລະອາຍແກັສ Steel Lost Wax Casting Parts. ຜູ້ຊ່ຽວຊານດ້ານການຫລໍ່ຂີ້ເຜີ້ງທີ່ສູນເສຍຂອງພວກເຮົາຈະຢູ່ທີ່ນັ້ນເພື່ອຊ່ວຍທ່ານໃນການແກ້ໄຂທີ່ດີທີ່ສຸດທັງຫມົດ. ຕອບສະຫນອງຄວາມຕ້ອງການຂອງທ່ານສໍາລັບຜະລິດຕະພັນທີ່ທ່ານຕ້ອງການOff ທາງດ່ວນອຸດສາຫະກໍາເຫຼັກ Casting Parts

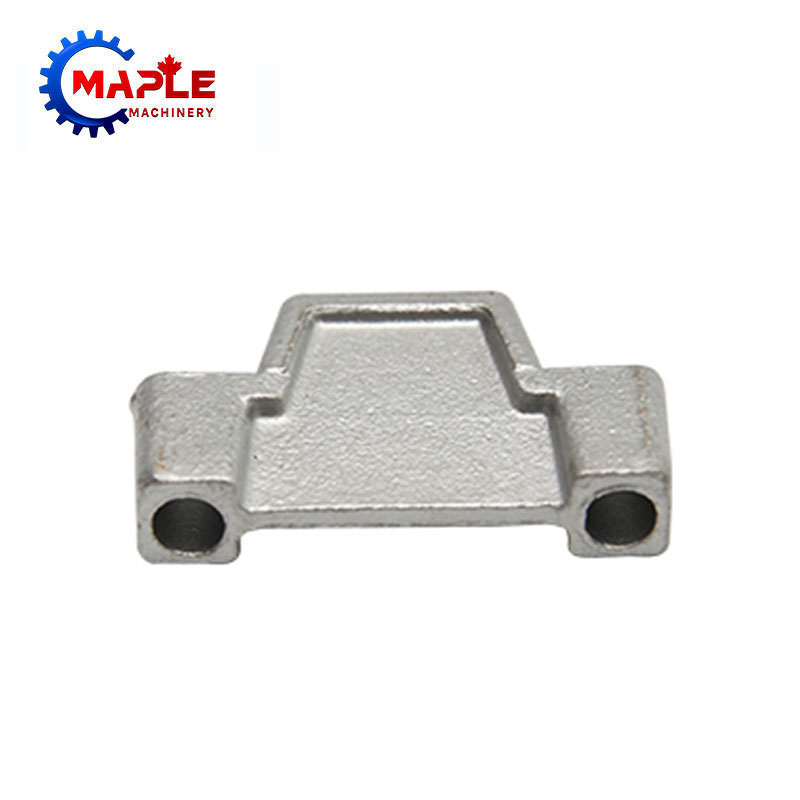

MapleMachinery ມີຄວາມຮູ້ຫຼາຍກວ່າ 20 ປີໃນໂລຫະປະສົມທີ່ມີຄວາມເຂັ້ມແຂງສູງ, ໂລຫະປະສົມ manganese ແລະcastiron. ພະແນກວິສະວະກໍາແລະການຂາຍທີ່ມີປະສົບການຂອງພວກເຮົາໃຊ້ຄວາມຊໍານານຂອງພວກເຂົາເພື່ອສະຫນອງຊິ້ນສ່ວນເຫຼັກກ້າຂອງ Off Highway ທີ່ມີຄວາມເຂັ້ມແຂງສູງເພື່ອຕອບສະຫນອງຄວາມຕ້ອງການຂອງລູກຄ້າທາງລົດໄຟໃດໆ. ພາກສ່ວນຂອງພວກເຮົາຖືກອອກແບບຢ່າງແນ່ນອນດ້ວຍວັດຖຸດິບທີ່ມີຄຸນນະພາບສູງເພື່ອຮັບປະກັນວ່າພວກເຮົາສະຫນອງໃຫ້ແກ່ລູກຄ້າທາງລົດໄຟທີ່ມີສ່ວນທີ່ມີຄວາມເຂັ້ມແຂງ tensile ສູງ, ການຕໍ່ຕ້ານ corrosion ແລະປະສິດທິພາບທີ່ດີທີ່ສຸດ. MapleMachineryhas ຍັງໄດ້ພັດທະນາໂລຫະປະສົມທີ່ກໍາຫນົດເອງແລະເປັນເຈົ້າຂອງສໍາລັບພາກສ່ວນທີ່ມີຄວາມສ່ຽງ, ແລະພວກເຮົາມີຄວາມສາມາດໃນການຕອບສະຫນອງຄວາມຕ້ອງການສະເພາະຂອງໂຄງສ້າງຈຸນລະພາກແລະຄຸນສົມບັດທາງກາຍະພາບອື່ນໆ.ອຸດສາຫະກໍາຫນັກສະແຕນເລດ Casting Parts

ເຄື່ອງຈັກ Maple ເປັນຜູ້ຜະລິດຊັ້ນສູງຂອງອຸດສາຫະກໍາຫນັກສະແຕນເລດ Casting Parts ໃນປະເທດຈີນທີ່ມີລູກຄ້າພໍໃຈໃນທົ່ວໂລກແລະຊື່ສຽງທີ່ມີຊື່ສຽງໃນອຸດສາຫະກໍາການຫລໍ່ຫລອມໂລຫະ. ລາວມີປະສົບການການຜະລິດເກືອບ 20 ປີໃນຂົງເຂດສະແຕນເລດ. ເຄື່ອງຈັກ Maple ໂດຍສະເພາະແມ່ນສາມາດສະຫນອງຜະລິດຕະພັນການຫລໍ່ເຫລໍກສະແຕນເລດທີ່ມີຄວາມຊັບຊ້ອນ.ເຄື່ອງຈັກການກະເສດເຫຼັກ Forging Parts

ສໍາລັບຫຼາຍກວ່າ 20 ປີ, Maple Machinery Co., Ltd., ຕັ້ງຢູ່ໃນ Ningbo, ຈີນ, ເປັນຜູ້ຜະລິດມືອາຊີບຂອງ forgings ຕາຍປິດ, ຊ່ຽວຊານໃນການສະຫນອງລູກຄ້າດ້ວຍພາກສ່ວນເຫຼັກ forging ເຄື່ອງຈັກກະສິກໍາຄຸນນະພາບສູງ. ນອກຈາກນັ້ນ, ພວກເຮົາຍັງສາມາດໃຫ້ບໍລິການມູນຄ່າເພີ່ມອື່ນໆສໍາລັບຜະລິດຕະພັນສໍາເລັດຮູບ. ດັ່ງນັ້ນ, ຖ້າທ່ານຕ້ອງການຊິ້ນສ່ວນ forging ແລະເຄື່ອງຈັກ, ກະລຸນາຕິດຕໍ່ພວກເຮົາ!ອຸດສາຫະກໍາຂຸດຄົ້ນບໍ່ແຮ່ຊິ້ນສ່ວນການຫລໍ່ເຫລໍກສະແຕນເລດ

MapleMachinery ມີປະສົບການໃນອຸດສາຫະກໍາຂຸດຄົ້ນບໍ່ແຮ່ໂລຫະສະແຕນເລດ Casting Parts. ດ້ວຍຄວາມສາມາດທີ່ເຂັ້ມແຂງໃນການຫລໍ່ເຫລໍກສະແຕນເລດທີ່ຫລາກຫລາຍ, ພວກເຮົາສະຫນອງການຫລໍ່ຫລອມສະແຕນເລດທີ່ກໍາຫນົດເອງແລະສ່ວນປະກອບສໍາລັບອຸດສາຫະກໍາຂຸດຄົ້ນບໍ່ແຮ່. ພວກເຮົາສາມາດຮັບປະກັນທ່ານຂອງຄຸນນະພາບສູງອຸດສາຫະກໍາການຂຸດຄົ້ນບໍ່ແຮ່ສະແຕນເລດ Casting Parts. ພວກເຮົາເຮັດວຽກກັບລູກຄ້າຂອງພວກເຮົາເພື່ອຮັບປະກັນວ່າຜະລິດຕະພັນ / ອົງປະກອບການຫລໍ່ເຫລໍກສະແຕນເລດສາມາດຜະລິດຄຸນລັກສະນະທີ່ຕ້ອງການໃນຄ່າໃຊ້ຈ່າຍທີ່ມີປະສິດທິພາບທີ່ສຸດ. ພວກເຮົາພະຍາຍາມກາຍເປັນຄູ່ຮ່ວມງານຕ່ອງໂສ້ການສະຫນອງສະແຕນເລດທີ່ດີທີ່ສຸດສໍາລັບລູກຄ້າຂອງພວກເຮົາ.ເຄື່ອງຈັກການກະເສດສະແຕນເລດ Forging Parts

Maple ມີປະສົບການຫຼາຍກວ່າ 15 ປີໃນການຜະລິດຜະລິດຕະພັນ forged ສໍາລັບເຄື່ອງຈັກກະສິກໍາ. ເຄື່ອງຈັກການກະເສດສະແຕນເລດ Forging Parts ພວກເຮົາສາມາດຜະລິດຜະລິດຕະພັນ forging ກະສິກໍາທີ່ມີຄວາມແມ່ນຍໍາໂດຍຜ່ານການປຸງແຕ່ງຜະລິດຕະພັນອັດຕະໂນມັດ. ຕອບສະຫນອງຄວາມຕ້ອງການທີ່ແຕກຕ່າງກັນຂອງລູກຄ້າ. ພວກເຮົາຮັບປະກັນການປະຕິບັດຂອງຜະລິດຕະພັນຂອງພວກເຮົາ. ໃນທາງກົງກັນຂ້າມ, ພາຍໃຕ້ຂອບຂອງຄວາມເຂົ້າໃຈຂອງລູກຄ້າແລະຕະຫຼາດ, ພວກເຮົາກໍາລັງວາງແຜນຢ່າງລະມັດລະວັງເພື່ອຮັກສາຄວາມສົມບູນຂອງລະບົບຕ່ອງໂສ້ການສະຫນອງແລະຕອບສະຫນອງຄວາມຕ້ອງການຂອງລູກຄ້າໃນສະພາບທີ່ດີທີ່ສຸດ.

ສົ່ງສອບຖາມ

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy